A. Battery cage system:

Most of the commercial layers today are kept in cages. This is particularly true in countries where the production processes are highly automated. The birds are easier

to manage in cages.

Cage types:

Many types of cages exist but the stair-step double decker type has become popular because unlike the vertical multi-stacked system, it does not require dropping boards or cleaning belts below the upper decks of cages. However, bird density per given volume house is lower for the stair-step cages compared to the stacked types. Cages should be placed in open sided houses with dwarf walls. Under very hot conditions, the house may be no more than a roof over the cages.

Stocking density:

It has been proved that when caged birds are fewer in number, they tend to waste more feed. Results of many researchers conducted in the last decade with regards to how much we can crowd layers in cages have, however, indicated that crowding is more profitable only when egg prices are high and feed costs are low. Attaining high egg prices without corresponding increase in feed cost is very unlikely in this country.

Manure Disposal:

Where small (backyard) or medium size farms are involved, manure accumulation may not pose much

problems. The manure produced can be collected and spread on farmlands. This method is easy and less expensive. However, in large-scale operations consisting of thousands or millions of

layers, and with land becoming scarce, manure disposal may become a serious problem. Lagoons, oxidation ditches, drying (dehydrating) and besides these methods being expensive, there is

still the odour problem and / or the need for final disposal of the treated manure. Poultry manure can also be fed to animals, particularly ruminants, after it had been treated. Proper disposal of manure is necessary so that offensive odour do not accumulate and pollute the neighbourhood. Apart from constituting a

nuisance to the birds themselves by attracting many flies, these odours and the flies make the working environment

uncomfortable for the attendants.

Cage-Related Problems:

Layers kept in cages sometimes develop some problem whose specific causes have not been ascertained. Such problems are not common among layers managed on the floor. The main cage-related problems most commonly encountered are cage layer fatigue (birds are unable to stand due to weakened bones), fatty liver syndrome (lots of the oviduct to retract after laying) and egg drop syndrome. Stress may be involved in cage layer fatigue. However, it does not seem to have any adverse effect on egg production. The proper maintenance of automatic waterers and feeders are critical. A block in the water line for example can lead to a sharp drop in egg production.

B. Deep litter floor system:

Install nests and fresh nesting material

such as wood shavings, rice hulls or sawdust. Well-designed nests should be provided to reduce time needed for caring for the laying flock and the eggs. Nests may be made of wood or metal and of varying arrangements, but should provide for convenience in egg collection. They may be placed in the middle of the pen or along the walls inside the building. Provide one nest measuring 30cm (12”) wide, 35cm (14”) high and about 30cm (12”) deep per 4 hens. For community nests should be cleaned regularly and new nesting materials added as needed to produce clean eggs.

The litter should be stirred frequently and new materials added.

Wet and “caked-over” spots should be removed and replaced with fresh, dry litter.

A common problem with hens on deep litter is floor eggs. Eggs laid on the floor easily become dirty and are susceptible to

breakage. The following management practices will help to ensure that the birds lay inside the nests rather than on the floor:

1. Have nests in the laying house before the pullets are housed or introduced the nests before the pullets commence laying

2. Provide adequate, well-ventilated nests to prevent overcrowding

3. Round off corners of the house, which serve as nesting places

4. Close nests at nights

5. Provide nests with clean nesting materials

6. Use darkened nests and place them in darker sections of the house.

Feeds and Feeding

Layers mash may contain between 2400 – 2800 Kcals of ME/kg of diet and 16 – 17 per cent protein. The peculiarity of layer’s feed, however, is its high calcium content, which may be up to 3.5 per cent. The high

calcium is necessary for laying down the eggshell.

In recent years, phase feeding of layers has been advocated to be in line with the different phases of an egg production profile. The first phase start at point of lay to the period of peak production i.e. between 20 – 35 weeks, the second phase begins at 35 weeks and ends at about 55 weeks while the third lasts to the end of lay. Under such a system the ration for

phase one should have 17 per cent protein, phase two 16 per cent and phase three 15 per cent protein. This takes cognizance of the differences in egg production during the three phases. The calcium level however, should be slightly increased from phase one to phase three to minimise

egg breakage which normally increases with age of the hen. Feed and water should be given liberally.

Management Guide for Layers

The following is a summary of management routines for laying hens:

1. Provide optimum space per bird. A space requirement of .186m (2sq ft) is adequate at point of lay

2. Introduce the pullets to layer’s mash preferably after the first eggs have been dropped (a production level of 2-5% )

3. Inspect birds daily for any signs of disease or abnormal behavior

4. Maintain accurate records of feed consumption, egg production and disease control measures. A sharp drop in feed consumption is often the first indicator of a pending disease outbreak or response to a major environmental stress.

5. Under hot weather conditions, provide plenty of cool drinking water, if possible, use artificial lights in the early mornings (from about 3:00 am) to stimulate feed consumption during the cooler times of the day.

6. Always enter the house courteously, rude entrance can create hysteria

7. Regularly cull unproductive birds. Removal of such hens creates more space for the remaining birds and saves on the feed cost that would have been expended on them. These birds may also fetch a

better price at the time of culling than if they were left to be older before sale. All layers should be sold off after about one year of lay unless they are still economically productive

8. At the first signs of disease or any other problem, set up the preventive or corrective measures promptly

9. Prevent feed wastage.

Egg Collection and Handling:

The chicken egg is one of God’s most

wonderful creations. Inside it is a warehouse of nutrients in such a way

that they can form a chick if the egg is fertile. This concoction of nutrients is held inside the shell, built in such a way that it is strong to bear the weight of a brooding hen but weak enough for the completely

developed chick to break through at hatching time. The shell is also porous enough to allow gaseous exchange between the inside contents and the external atmosphere.

This delicately designed bag of nutrients manufactured by the laying hen must be properly cared for if its original quality is to be retained during handling and storage. The conditions for handling and marketing of good quality eggs are as follows:

1. Provide adequate nests for hens of deep litter. The nest may have a hinged door at the top to facilitate easy collection of eggs

2. Keep litter dry. The egg is at its best at the point of oviposition.

To prevent it from picking up dirt, the litter should be kept fresh by regular turning of the older litter, removal of wet spots and

topping up with fresh dry litter when older litter becomes “caky” or too moist.

3. Collect eggs at least three times a day. Frequently egg collection prevents the unnecessary accumulation and trampling of eggs by hens. The use of paper or plastic egg trays is best for egg collection because they make it possible to collect and stack eggs with minimum breakage.

4. Store eggs in a cool place. Egg quality deteriorates very rapidly in a hot environment. The optimum temperature for storing eggs is about 130 C (55.40F) at 75 – 80 per cent relative humidity.

5. Use the egg room only for eggs. Eggs should be kept away from onions, kerosene and other products with pungent odour that eggs might absorb.

6. During periods of egg glut, spraying or dipping eggs in minerals oil (groundnut oil, cotton seed oil or palm oil, etc.) for one minute will preserve egg quality under normal room storage conditions for about four weeks.

Selection and Culling

The selection and culling of unproductive hens from the flock has the following advantages:

1. More floor space will be created for the good producers.

2. Saves on the feed cost of maintaining unproductive birds

3. Culling at an earlier age may fetch a better market price for the bird

4. May lead to a reduced incidence of diseases

5. It results in an improvement of feed efficiency for the entire flock.

Culling is a process that should actually begin at day old. Weak, diseased and unthrify birds should continuously be culled out during the growing period.

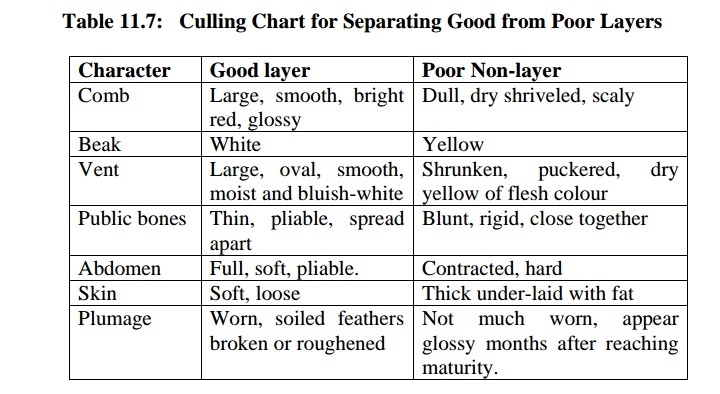

In laying flocks culling should commence soon after the hens attain peak production. The characteristics used to distinguish between good and bad layers are summarised in table below:

The best time to cull is in the evening just after dark using a flashlight, but culling can also be done during the day.

The age at which to dispose of old layers is the point at which the cost of egg production exceeds income from sale of eggs. Layers can be recycled by using a force molting programme.

Management of Breeders

Breeders are essentially managed like layers except that management procedures must be more strictly adhered to. The following management practices must be given special attention.

• Selection and Culling: Must be routinely and vigorously practiced.

• Vaccinations: There may be need for some vaccinations at point of lay which can serve to transfer immunity from hen to chicks e.g. IBD vaccine.

• Feeding: Feeding breeder mash, which usually contains a higher level of vitamins and some minerals than the regular layers mash.

Feed restriction is often necessary for broiler breeder. A common practice is to limit feeding to only about 80 per cent of daily feed intake. Such diets must, however, be optimally fortified with

minor nutrients.

• Egg Collection: Collection is at least five times a day.

1 Comments

Nice information, You have provided very important and essential data for us. It is valuable and informative for everyone. Keep posting always. I am very thankful to you. Thanks once again for sharing it. sterilox produce fresh

ReplyDeleteComment